Ceramic Capacitors Technology

Ceramic capacitors are dominating capacitor market in number of fields:

- Largest volume capacitor technology (by far)

- Largest value capacitor technology

- Smallest dimension discrete components among all passives

- High flexibility of design to meet specific requirements such as low ESL / high frequency operation

- Strong presence in both low voltage, low power and high voltage, high power applications

despite all the above benefits there are some limitations of the technology that has to be understand for the correct use and design-in.

C 2.9 INTRODUCTION to CERAMIC CAPACITORS

Within the electrostatic capacitor family we can distinguish two groups: the organic film capacitors described on the foregoing pages and capacitors with inorganic dielectrics. Of these dielectrics we will start with the dominating ceramic materials.

C 2.9.1 Construction

The capacitors consist, as the name tells us, of some kind of ceramic. The manufacturing process starts with a finely grounded ceramic powder mixed to an emulsion of solvents and resin binders. In the first manufacturing step the emulsion then is dried to a soft film and screen printed with an electrode paste, historically it was a compound of palladium or silver and palladium + binding agents. Due to the high cost of palladium this termination style was replaced by metals like copper and nickel, so called base metal electrodes (BME) that is a majority of todays MLCC designs.

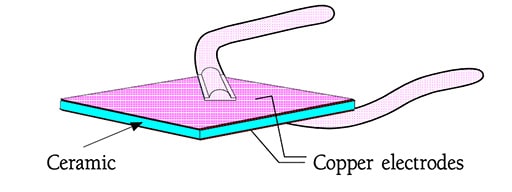

So called tube capacitors are extruded out of a nozzle and are covered with an electrode paste on the inside and the outside before it’s sintered to its definite material structure. In the same way the Single Layer Ceramic Capacitor (SLCC or just SLC) consists of one dielectric layer. The ceramic is covered with an adhesive layer of, for example, chrome nickel as a base for copper electrodes. On the electrodes leads are soldered as shown in the principle Figure C2-69, before the component is encapsulated in lacquer or epoxy.

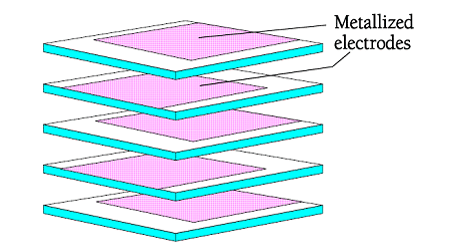

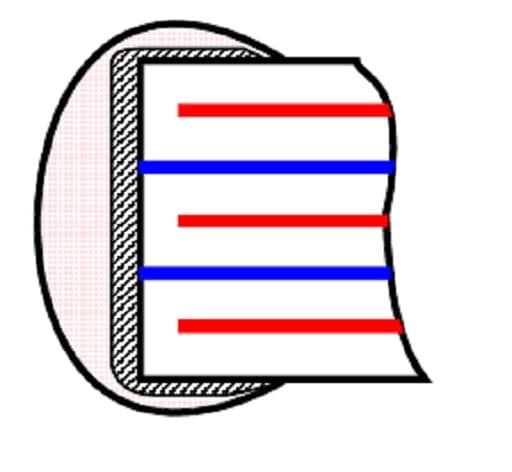

The most common design of a ceramic capacitor is the multi layer construction where the capacitor elements are stacked as shown in Figure C2-70, so called MLCC (Multi Layer Ceramic Capacitor). The number of layers has to be limited for reasons of the manufacturing technique. The upper limit amounts at present to over 1000. Besides economical reasons come into play. On larger case sizes, stacking operation becomes less productive and raise the price steeply at higher capacitance values. The lowest capacitance values are achieved by only two layers, often separated by double ceramic layers.

In the conventional so called dry method the ceramic emulsion is dried on a conveyor belt before it is separated from the supporting bed. After it is cut into “primary sheets” that are screen printed with electrode paste for a large number of chips. These primary sheets then are stacked in an accurate steel frame and pressed to a solid piece in order to make it possible to cut out the separate chips from the stack with the electrodes in alternating positions as shown in Figure C2-70 below.

In the latest variant of this method one utilizes a conveyor film for the ceramic emulsion and has thus succeeded in reducing the dielectric thickness to 3 μm (0.1 mil). Here the quality implies manufacture in extremely “clean rooms”, i.e. in rooms with filtered air and control of the number and size of particles.

Before the variant with a conveyor film was used in the dry method, the so called wet method was becoming more and more common. There the stage with handling of “primary sheets” is skipped by letting the emulsion dry in “primary sheet frames”. In combination with better milling methods for the ceramic powder and a higher material purity the wet method makes it possible with thinner dielectrics without a growing failure rate.

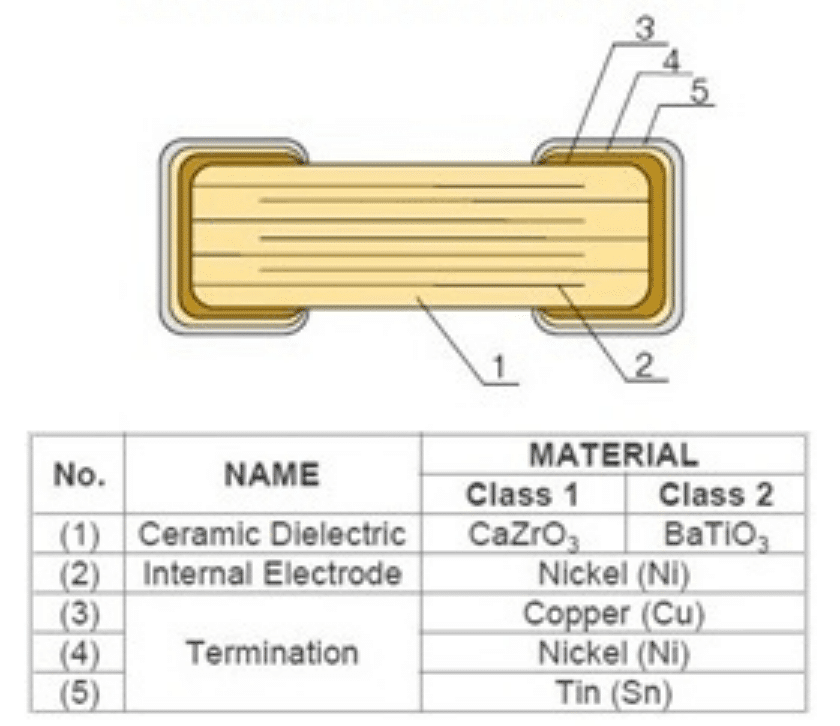

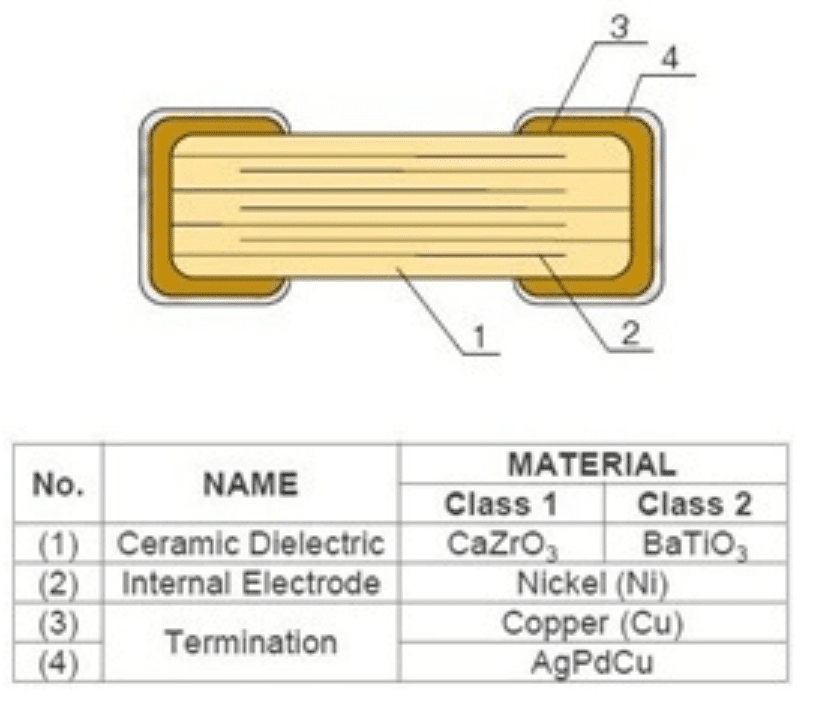

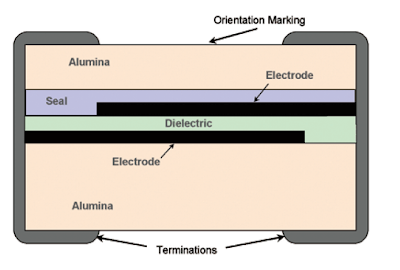

Figure C2-70. MLCC capacitor structure with BME and AgPd terminals

There are two basic termination structures – BME Base Metal Electrodes based on copper and nickel metals and PME Precious Metal Electrodes based on silver palladium metals. The original technologies were using mostly PME structure but palladium high prices pushed industry to look for alternatives. Advantage of PME has been its TCE compatibility with the glass dielectric and thus lower stress during firing process. However, BME is now the dominating structure and subjected to the latest developement, thus higher CV capacitors are available in BME configuration, while PME is used in mission critical applications such as space or defense.

The separate cut loose chips are subjected to a first heat treatment (burn-out) where the organic binding agents – also those being part of the electrode paste – are gasified and diffuse through the not yet sintered ceramic. If this process is forced too fast gas bubbles are formed that will separate electrodes and ceramics and results in so called delaminations (Figure C2-71).

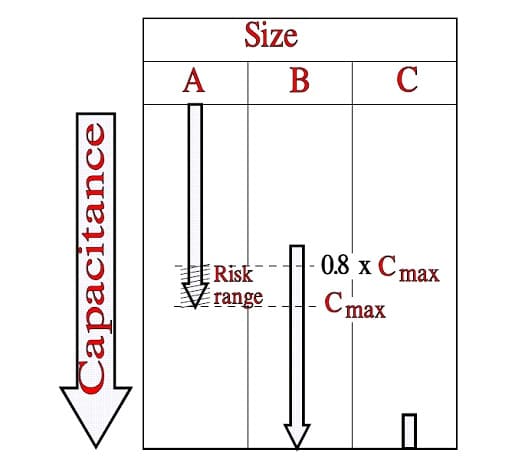

The risk with a delamination also increases with the number of layers. Primarily it depends on the quantity of electrode metal in the ceramic and the differences in TCE (coefficient of expansion) of these materials. At the maximum of capacitance in a certain chip size a delamination is nearly unavoidable.

Now a delamination may not be that catastrophic that we fear. If the capacitor is not subjected to extreme humidity that might diffuse into the cavities and the soldering is executed without any unsymmetrical heat conduction that may cause cracks in the ceramic we will never become aware of any delaminations (unless we deal with high voltage capacitors where the corona effect may be dangerous). It’s the authors opinion that only soldering with a soldering iron will cause such temperature gradients that the ceramic may crack. There are, however, other reasons why it may be advisable to avoid the highest capacitance values.

The dielectric thickness, the number of electrode layers and the active capacitive area determine the capacitance in a certain chip size. The thickness is varied by using one or several layers. But when we on the way towards higher capacitances pass from two to one layer the risk of short-circuit failures increases. It will, of course, be at maximum when we pack the chip with the maximum number of layers. At the same time the risk of delamination increases. A practical limit where it may be advisable to avoid this twofold risk range by a size exchange is approximately 20% below the usually starts overlapping in next chip size (Figure C2-72 above).

If the component operates at high electric field strengths or in severe mechanical acceleration or chock environments we should in any case avoid maximum capacitance values in that size class, i.e. reduce the capacitance or increase the mechanical size.

We can also buy “high-rel” components, for example according to MIL-C-123 that specifies limits for the delamination extent and states methods for X-ray diagnosis. The price, however, will be approximately 20 times higher than that of a conventional standard component and the success with the X-ray check is debatable. Other methods with ultrasonics are developed but the result is many times difficult to interpret. Besides such equipments are expensive. In conclusion only “space” and other “high rel” applications motivate the price we must pay for the increase in quality.

The burn-out process shouldn’t be forced too fast because of provoked delamination. On the other hand it may not last too long. Then impermissible much of the palladium content of the electrode paste will oxidize. In other words the time-temperature profile must be kept at an optimum level for the ceramic and electrode material.

After the burn-out process follows the considerably faster sintering of ceramic and electrode materials. Also here check of the time-temperature profile is extremely vital, not least the cooling time if we shall avoid micro-cracks in the ceramic.

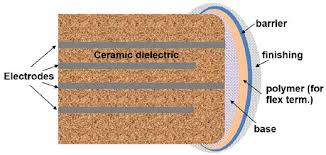

After the sintering terminations are applied which consist of

- farthest BME or Ag/Pd in good adhesion to the ceramic, 15…40 μm (0.6…1.6 mils)

- possibly a barrier layer (Ni) that will prevent silver from dissolving into the solder, 1…3 μm (0.04…0.1 mil) and

- farthest out Sn, 3…10 μm (0.1…0.4 mil) or solder, 10…100 μm (0.4…4 mils) (Figure C2-74).

If the inner electrodes consist of nickel or copper compatible termination materials have to be utilized. For that reason nickel or copper based compounds are developed for outer terminations. They have a low migration and need only to be covered with a solderable alloy.

Electro-plating of tin as the outermost layer gives an evenly thick layer also on edges and corners. But because of a perpendicular orientation of the tin crystals against the surface they are leaving access to oxidizing oxygen if the tin layer is too thin. Therefore it should rather be 10 than 3 μm thick (0.4 mils rather than 0.1 mil). Hot or dip tinning creates a very tight layer but with an uneven thickness. The covering on the corners becomes thin.

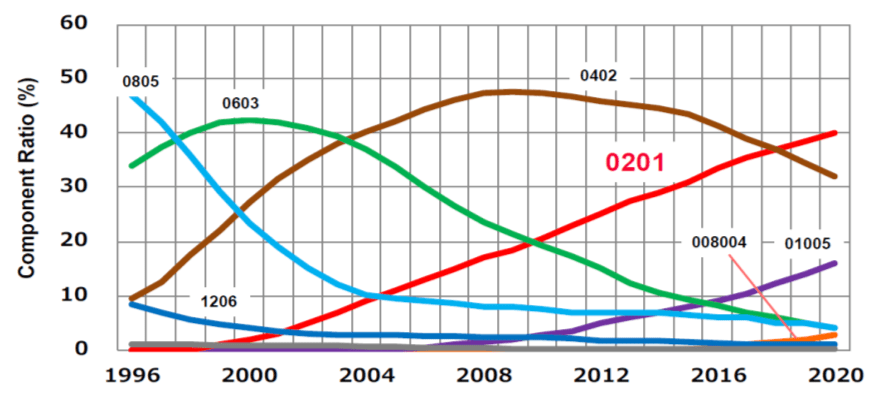

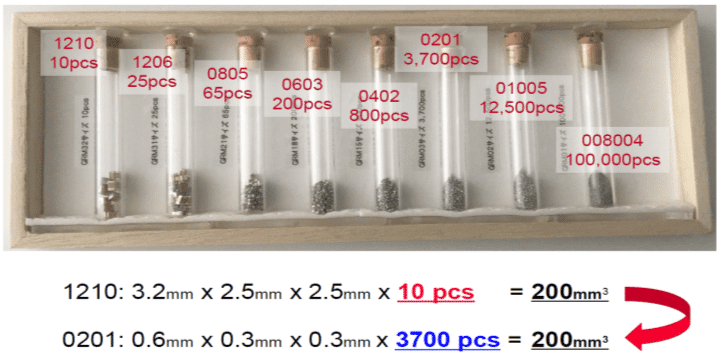

Ceramic chips for surface mounting looks in principle like the one in Figure C2-74. MLCCs are by far the leading downsizing and miniaturization technology among passive components. Chart bellow is illustrating shift of the case size mix in MLCCs. While the most popular case size in 1995 was 0805, 0603 in 2000, 0402 in 2009, the most often used case size since 2018 is 0201 that is a capacitor in dimensions 0.6×0.3×0.3mm. The smallest so far MLCC in mass manufacturing is 008004 case introduced to volume production in 2019 with dimensions as small as 0.2×0.1×0.1 mm.

The enormous volumetric downsizing is illustrated in figure bellow right – about the same volume taken by 10 pieces of 1210 case size is occupied by 100 000 pieces of 008004 capacitors !

Flexible soft termination

Fail Safe Multilayer Ceramic Capacitors (MLCCs)

Multilayer ceramic capacitors are highly susceptible to mechanical cracking due to their brittle nature. It is necessary for circuit board manufacturers to ensure that their board handling techniques do not expose boards to excessive bending (board flex) during manufacturing and operation. Some of the processes that can expose boards to excessive bending include mounting in assembling and depanelization. Use of unsupported input/output edge connectors and pick-and-place equipment can also cause excessive bending.

Standard MLCCs have no crack protection and they are normally used for non-critical applications.

Soft termination (Flexiterm, Flexcrack etc … trade names) are based on principal to introduce a soft, conductive layer (usually conductive polymer) to the MLCC terminals that absorb mechanical stress. See figure on right.

These capacitors can withstand up to 2-5mm of board flexure without internal cracks. Beyond 5mm, capacitor will generally fail “open” and thus this style is the preferred solution today for automotive and higher reliability applications.

High Voltage SMT Ceramic Capacitors

Surface mount high voltage multilayer ceramic capacitors (HVMLCCs) appear to be pretty much identical to standard configuration MLCCs. They have the same basic form, fit and function, but there are several key differences.

Typically, as a matter of definition, high voltage MLCCs have rated voltages that are greater than or equal to 200VDC. High voltage MLCCs are typically available in EIA size from 0603 to 2225 or larger (metric 1608 to 5664) with voltage ratings from 200V to 5,000V or more. Smaller case high voltage MLCCs typically have lower maximum rated voltages (VRated) as the external terminals tend to be closer to each other in comparison to larger case high voltage MLCCs.

High voltage MLCCs are generally available with Class 1 (C0G) or Class 2 (e.g., Ferroelectric X7R) ceramic dielectrics with tolerances that are as good as +/-5% or better, to as wide as +/-20% or higher. Because of the generally thicker dielectric thicknesses used in the design and potentially the “cascade” or “floating electrode” type designs used, the maximum capacitance values available are significantly lower than standard MLCCs.

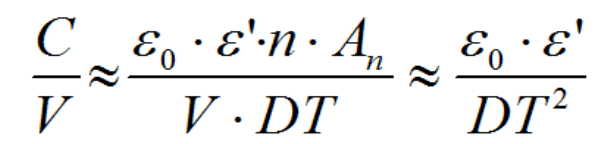

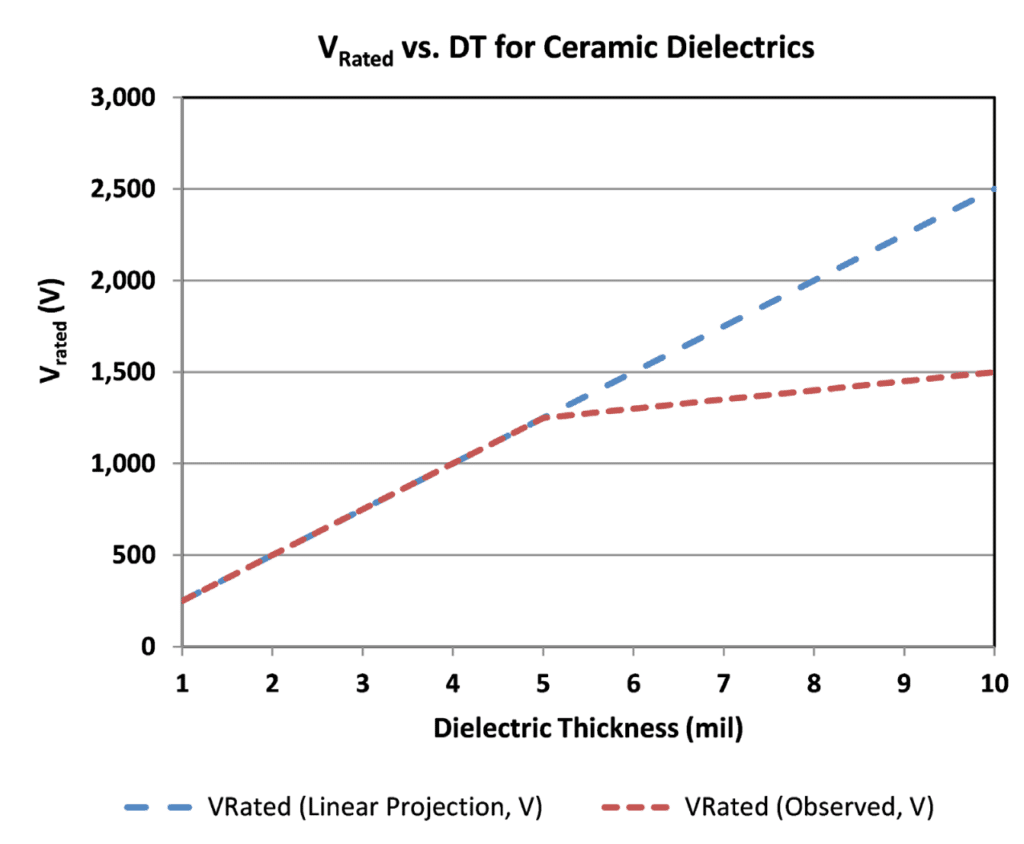

HVMLCCs appear similar to standard configuration MLCCs. It seems that it should be straight forward to design an HVMLCC of a given voltage rating; just keep increasing the dielectric thickness (DT) to enable the voltage rating desired as you would with a standard configuration MLCC. The rate of increase in DT used is typically about 200 to 250 Volts per thousandth of an inch (V/mil, or ~7.8 to 10 V/μm).

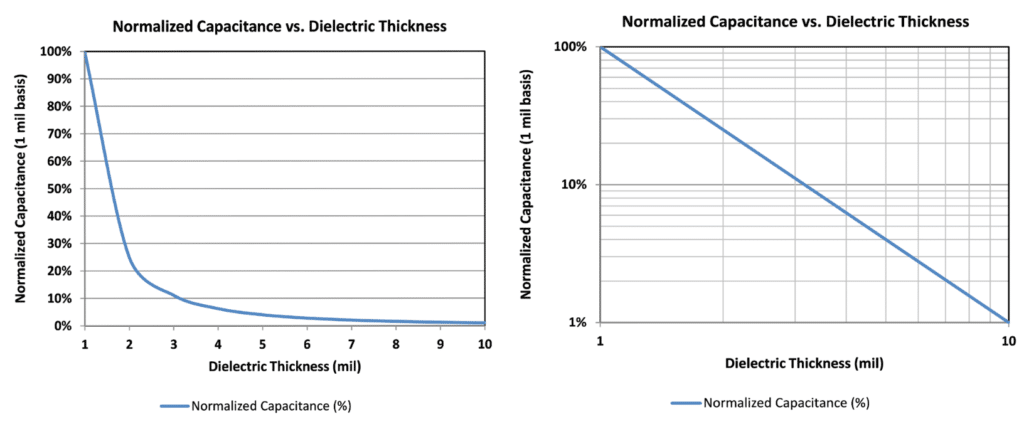

There is a penalty in capacitance per unit volume (C/V) using this approach to increasing rated voltage, as it requires increasing DT. The penalty in C/V is proportional to DT-2 following the relationship:

However, above ~1,500V, it gets more complicated than that. An example of the resulting penalty to C/V is illustrated in Figure below. As voltage rating is increased, DT must increase to the expense of C/V in a manner that is linear for the log-log relationship demonstrated on the right, where C/V is reduced 2 decade values for every one decade value increase in DT. Thus, as rated voltage is increased, capacitance per unit volume is reduced at a fairly dramatic rate.

The above penalty in C/V as voltage rating is increased is not the only factor to consider however as the above as-sumes that a constant rate of increase in DT is appropriate to achieve increased voltage rating. While this is true, typically to ~1,000 to ~1,500VRated ceramic dielectrics tend deviate from that rate as VRated is increased above ~1,000 to ~1,500V, resulting in a different VRated vs. dielectric thickness relationship that is of lower slope. A hypo-thetical example of this is given in Figure below.

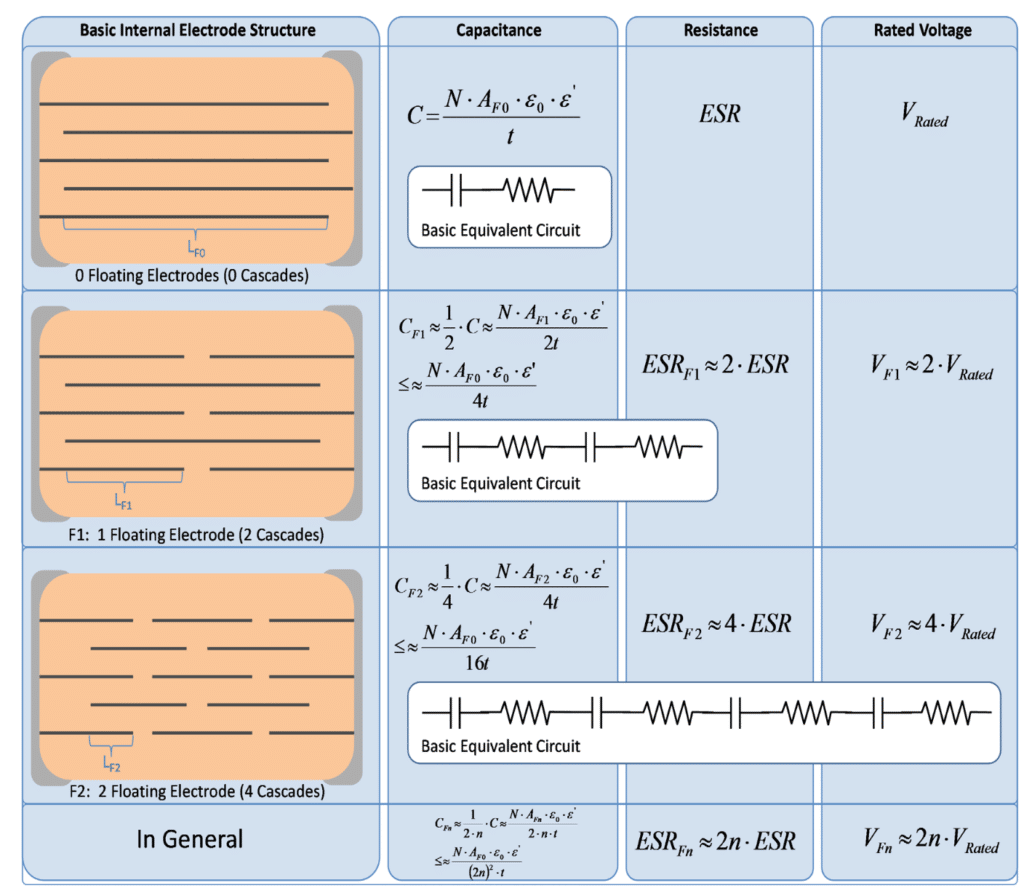

We can use floated electrodes (FE) or cascade electrode MLCCs to increase VRated with relatively minimized impact on C/V as compared to standard configuration MLCCs at lower voltages (i.e., <~1,000V to ~1,500V). As each FE has an additional margin area associated with it, the impact of additional margins on C/V in small case MLCCs (typically EIA 0603 and 0805) may be prohibitive, but for larger MLCCs (e.g., EIA 1206 to 2225) the impact is acceptable to relatively small.

As in Figure below, C/V decreases commensurate with (1/2n2), where n is the number of FEs within the design. VRated also increases with 2n as does ESR. The effect on ESR is largely compensated for however, as the two or more internal capacitors typically have more electrodes in each internal capacitor stack (N), thereby reducing ESR within each capacitor in series, and since the aspect ratio of said electrodes within each of the internal capacitors in series has relatively wide and short electrodes, which results in further decreased ESR. These two factors work together to reduce ESR such that the projected ESR increase is typically negligible, and may even be reduced in comparison to standard configuration MLCCs of similar VRated.

Other Construction Types

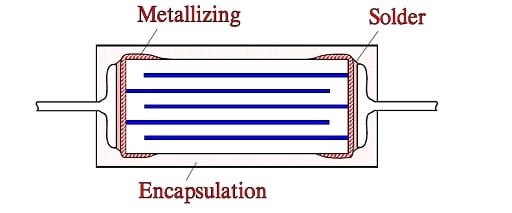

RF Thin Film Ceramic Capacitors

Thin-film ceramic capacitors are using a single-layer low loss ceramic dielectric packaged as a multilayer ceramic capacitor (MLCC) – see figure below. Its advantage is in very tight capacitance tolerance (even low batch to batch variation) and a single resonant point response. Thus such design are ideal for RF and microwave filter designs.

A thin-film capacitor has an extremely repeatable frequency response compared to MLCCs.It is also important to realize the limitations of thin-film capacitors used as band-reject filters. Since thin-film capacitors are typically only available in low capacitance values they are limited to relatively high-frequency band-reject filter designs. If dealing with low frequency designs, other filter methods must be utilized typically using high-Q multilayer RF capacitors.

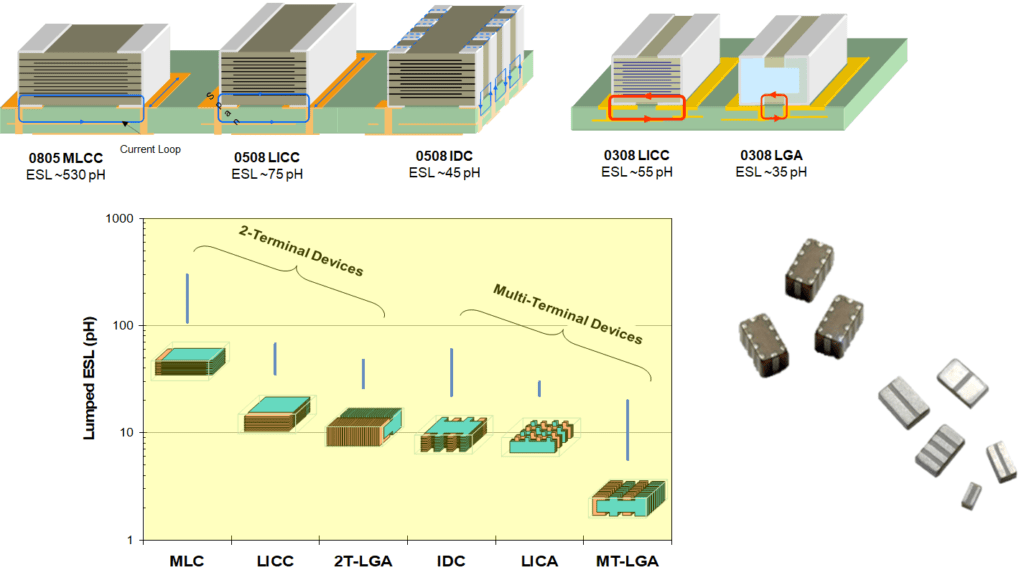

Low ESL designs

One of key MLCC stacking technology advantage is its flexibility in electrode / dielectric layers layout. This allows high customization level to match the technology with specific application field requirements. Low ESL, high frequency coupling is more and more important with the latest generation of processors. The following figure is illustrating possible design configuration to reduce ECL and enable higher frequency operation.

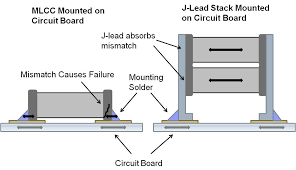

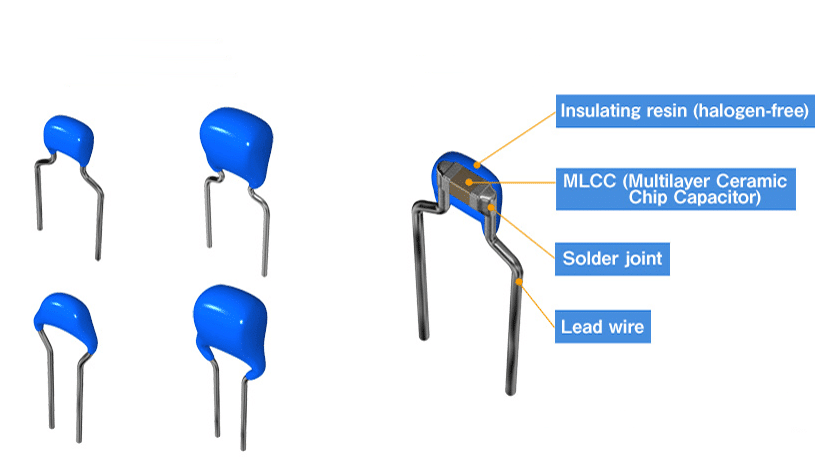

Lead mount MLCC

Lead mount components are supplied with leads. It can be encapsulated or stacked together by supported J-lead terminations, as in the following Figure C2-76.

The purpose of leaded MLCCs is not only in enabling of the technology for through hole assembly but in most cases reduce mechanical stress and risk of cracking at larger case sizes. This is commonly used in high rel industry or automotive to accommodate larger capacitance values while keeping high vibration robustness.

Figure C-76. encapsulated and leaded ceramic MLCC

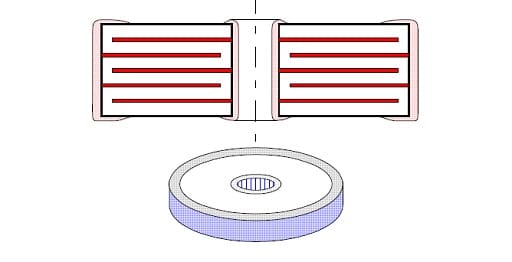

Discoidal

In filters and connectors another chip variant occurs, the concentric one called discoidal that are often used as a feedthrough capacitors.

C 2.9.2 Failure modes

Already during the construction report we have touched on some of the failure modes that may appear in ceramic capacitors. Probably the most common one in MLCCs is short circuiting at low voltage in high impedance circuits. It appears as micro-cracks in the ceramic. Under the influence of moisture and a polarizing voltage an electrolytic material transportation from one electrode to the other easily takes place. We call it “ionic migration”.

We get a short-circuit that to its character resembles the one that may occur in carbon contaminated self-healing sites in plastic film capacitors. Similarly the conductive path is extremely thin and is easily burnt away if the voltage exceeds certain minimum values. Should it on the other hand be too high we get a flash-over in the crack and this is hardly better.

It is well known that parts manufactured in older technologies had an increasing failure rate that started when the dielectric became thinner than 20…25 μm (» 0.8…1 mil). Even if some manufacturer’s technological progress has made the quality of thin dielectrics much better we still have to be cautious. The failure type is batch bound and manufacture dependent which among other things is connected with the sensitivity to dust and particles in the air.

Dielectric layers thinner than 50 μm (2 mils) require manufacture in clean rooms, i.e. rooms with filtered air and controlled number and size of particles. In other words knowledge about good manufacturers is a must. Certainly there are different methods to trace suspicious batches. In the so called “85/85 test” according to MIL-C-123 the capacitors are exposed to 85% RH at +85°C and maximum 1.5 V DC in series with 100 kΩ for at least 240 hrs. But the efficiency of this test is not one-hundred-per-cent.

Another failure that above all strikes the common SMD components is bad solderability and silver leaching in more severe soldering processes. In order to meet the solderability problem one ought to

- specify and check packaging method and component age and check the solderability in a wetting balance, at the relevant soldering temperature.

Hence storage of chips with their exposed terminations should be done in a protected environment. Above all we should be on our guard for cardboard boxes because they may have a sulfur content which will cover silver alloys with a sulfide layer that destroys the solderability.

The leaching problem can be met with requirements for a barrier layer / nickel barrier. But a general requirement may not be enough. The freedom of pores in the nickel layer and its thickness are important. Besides also here knowledge about the manufacturers is necessary.

There are many pitfalls in the form of poor cleaning from plating bath residues, negligence with the oxidation protection of the nickel layer etc. Finally the soldering process might be quite unsuitable for nickel barrier designs. The streaming solder from the wave soldering rapidly conveys heat to the component surfaces and especially to the hard, fast-wetting nickel barrier. Long before the ceramic body has got warm the nickel layer has reacted with its thermal expansion.

In chips larger than 1210 this leads to risk of cracks in the ceramic, inside the nickel barrier, especially if the layer is relatively thick. Therefore many leading manufacturers make larger sizes without any nickel barrier. But if we from serious manufacturers can find larger sizes with nickel barrier and they are not exposed to wave soldering but to the slower, more lenient processes like, for example, vapor phase, IR or hot air then chip sizes up to 2220 should be possible to use without any risk. Still larger sizes should have some kind of flexible terminals.

for introduction you can also check MLCC technology webinar from Kemet: