Film and Foil Organic Dielectric Capacitors

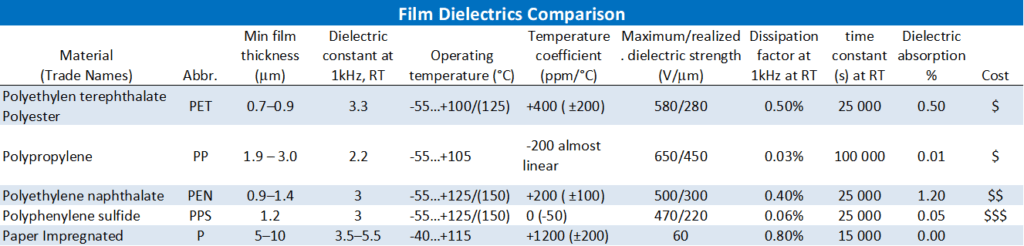

In this lesson we will review features of various organic polymer film (plastic) dielectric materials that we introduced partially in previous lesson on paper capacitors.

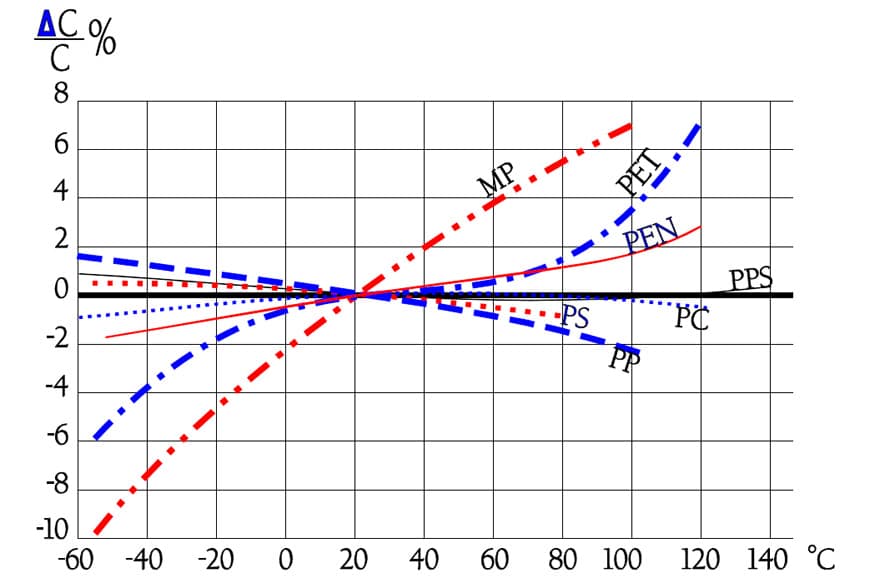

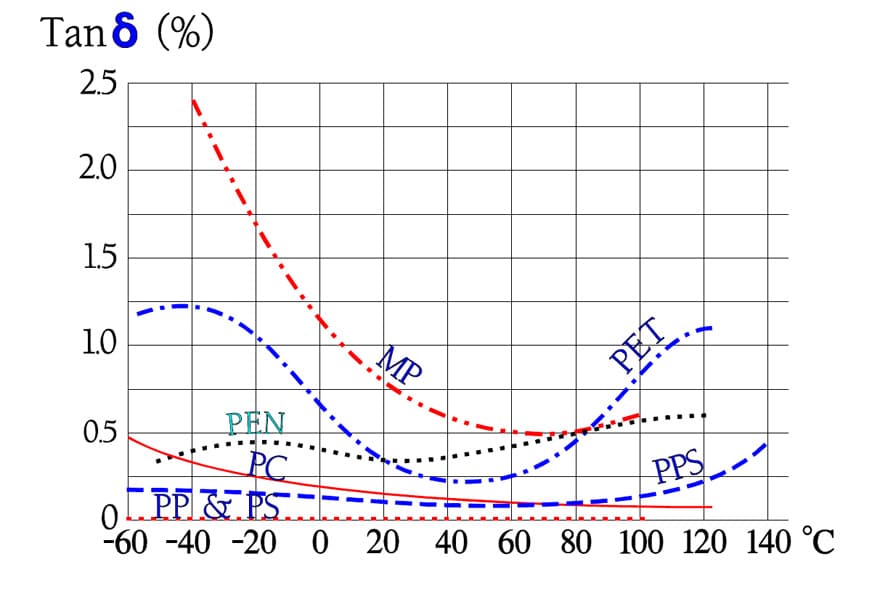

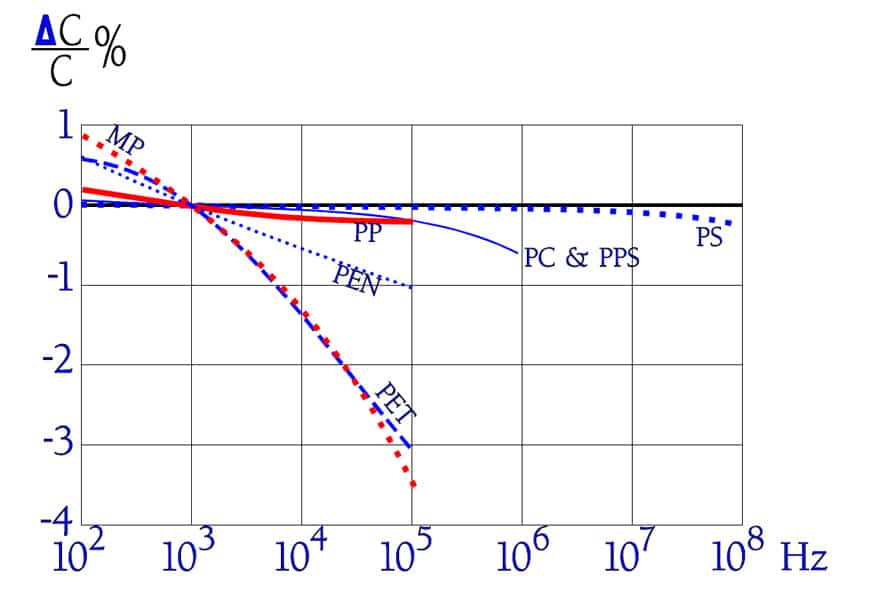

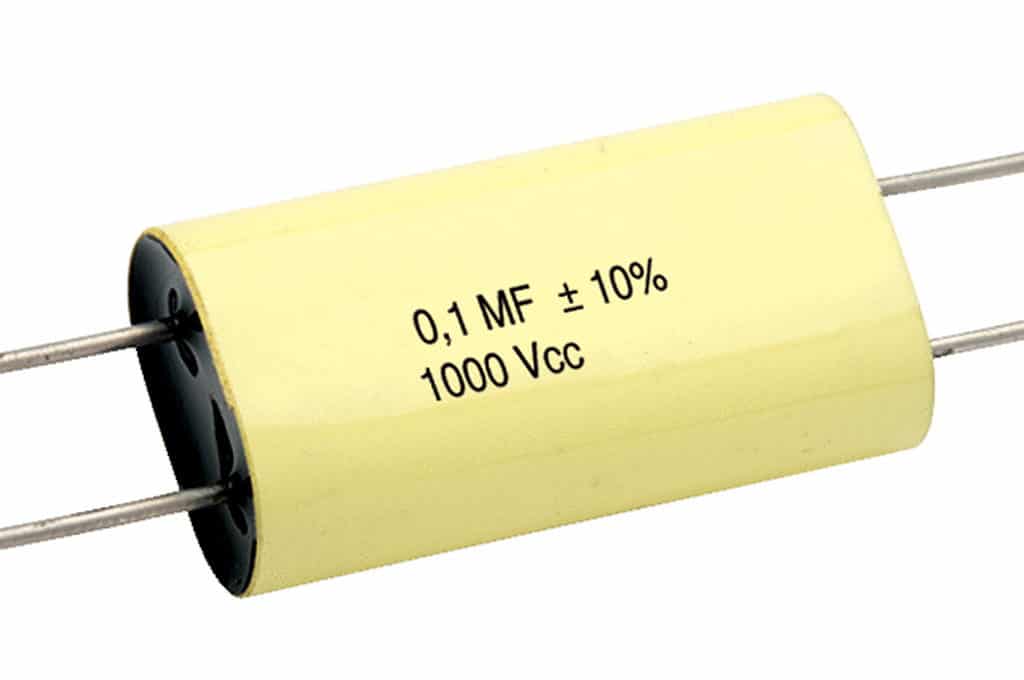

Polymer film capacitors are essential components in higher voltage and higher current circuits. Unlike most other dielectric systems, film capacitors feature low loss factor at very low temperature. Dielectric constant is not big, but they feature very high dielectric strength. In combination with long life and self-healing aging capabilities it makes them ideal choice for high voltage, high power systems.

Applications & Designs

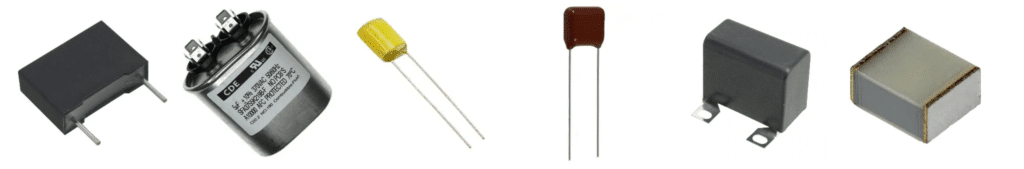

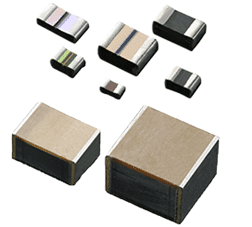

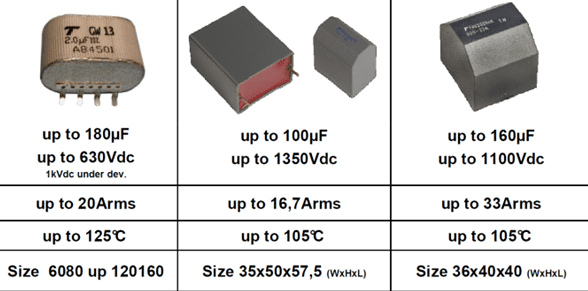

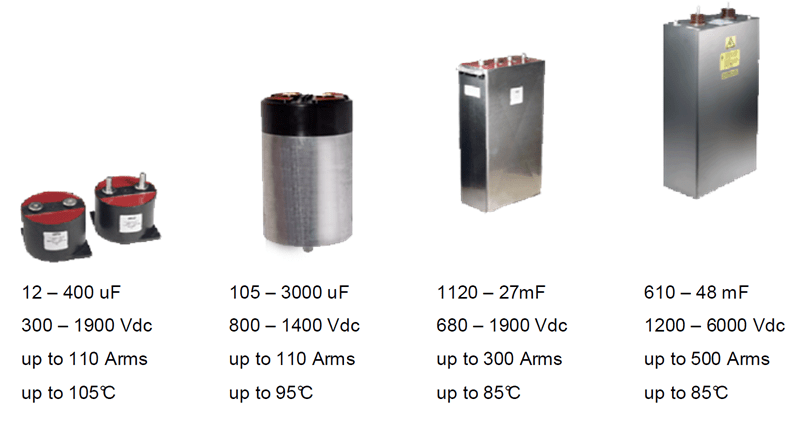

There are various forms of film capacitors on market from SMD chip style up to high power high voltage types:

SMD Stacked Chip

0.01uF – 15uF

30 – 400V

up to 125°C

Medium Power

High Power

Some typical examples of film capacitor applications:

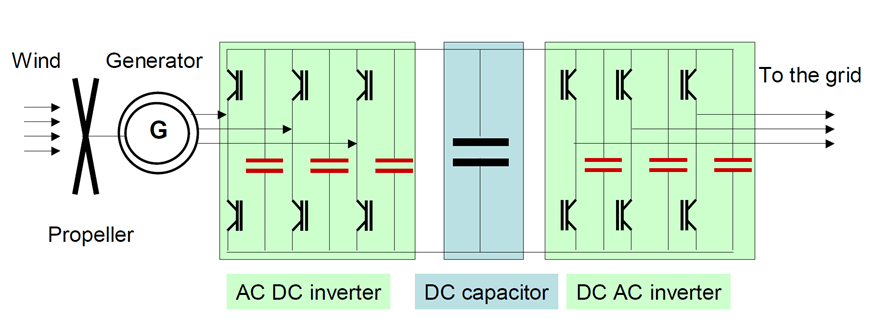

- DC link in automotive or renewable energy generators

- AC motor and light start

- Medical defibrilators

- Railway systems

- Defence and space hardware

- Energy distribution and power correction

In Summary -Key Attributes of Film Capacitors: